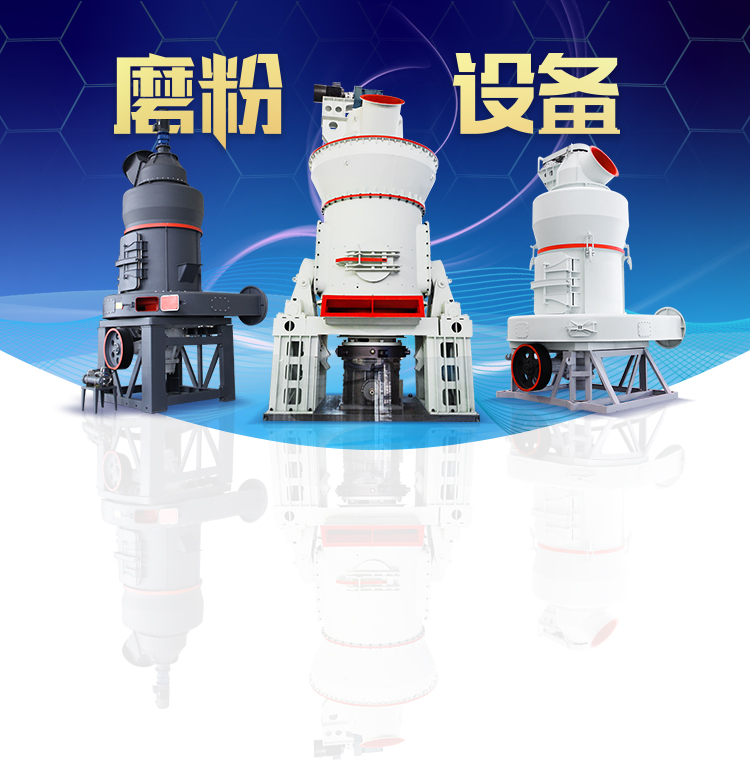

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Power Rating For T Ball Mill

.jpg)

Ball Mill Design/Power Calculation 911Metallurgist

2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk 2019年8月30日 How to do Ball Mill Parameter Selection and Calculation from Power, Rotate Speed, Steel Ball quantity, filling rate, etc read moreBall Mill Parameter Selection – Power, Rotate 2020年11月16日 In the following analysis capacity, T, is expressed in short tons per hour, tph, and power consumption, P, in kilowatts, kw Accordingly power consumption per unit of Ball Mill Capacity and Power Consumption Relationship to Mill 2024年10月13日 Motor Power: The motor power of a ball mill is an important factor in determining its grinding capacity Ball mills can be equipped with motors ranging from 10 kW Technical specifications and selection guide for ball mills

.jpg)

MODELING THE SPECIFIC GRINDING ENERGY AND BALL

2021年2月24日 Comparison of the ball mill power draw from the Denver slide rule and the proposed model Dashed line corresponds to y=x f L, and and T, fc) (L/D) ratio From this 1992年1月1日 Analysis of the historic mill power draw, site data on ball filling provided by mill grindouts, and applying the Morrell Power model (Morrell, 1993) to backcalculate approximate mill(PDF) Prediction of grindingmill powerthe desired motor power and drive rating, the maximum design mill speed, and the maximum design ball charge volume (Barratt, 1989) For single pinion and dual pinion drives, with 21 Mill drives: the desire for increased power and the2016年12月12日 Use this online calculators for Motor Sizing and Mill sizing as well as mill capacity determinators In extracting from Nordberg Process Machinery Reference Manual I Ball Mill Design/Power Calculation LinkedIn

.jpg)

Ball Mill Motor/Power Sizing Calculation 911Metallurgist

2015年9月15日 Optimize your ball mill's performance with 911 Metallurgist's guide on motor power sizing calculations Discover the key formulas and factors to accurately determine motor 2001年8月1日 Typical power consumption for a 5m diameter by 7mlong ball mill is between 25 and 35 MW The actual proportion of this energy usefully used in size reduction is thought Charge behaviour and power consumption in ball mills: 2024年10月13日 Motor Power: The motor power of a ball mill is an important factor in determining its grinding capacity Ball mills can be equipped with motors ranging from 10 kW Technical specifications and selection guide for ball mills2018年4月10日 A POWER BASED APPROACH FOR THE SELECTION AND COMPARISON OF BALL MILL LINERS by Olav Mejia Alarcon BA, Univ Nac Mayor de San Marcos, 1992 A A POWER BASED APPROACH FOR THE SELECTION AND

Navigating Ball Mill Specifications for Theory‐to‐Practice

2024年8月15日 By using mechanical energy, 1 modern highenergy ball mills have revolutionized the domain of mechanochemistry, paving the way for academia and the fine 2024年12月12日 While ball mills and tumbling mills are often grouped together, they aren’t identical: Ball Mills: Use metallic or ceramic balls to crush materials, focusing on fine particle sizes Tumbling Mills: Ball mills consume What Is a Ball Mill? Understanding How It 2010年11月1日 The JKMRC has developed effective models for predicting ball mill, au1ogenous mill, semi autogenous mill and crusher power draw When combined with comminution models they provide a powerful Consolidation and validation of several 1990年2月1日 where m p is in kW; D is internal mill diameter (meters), L is internal mill length (meters); J is total fractional charge loading of the mill; J B is the fractional mill filling by balls; ε A mill power equation for SAG mills Springer

.jpg)

Ball Mill Success: A StepbyStep Guide to

2024年8月8日 Ceramic Balls: Composed of materials like silicon nitride, alumina, and zirconia, ceramic balls are favored for their exceptional hardness and resistance to wear, corrosion, and high temperatures These properties 2024年4月29日 Ball mills are widely used for size reduction in mineral processing, but effective scaling from laboratory to industrial scale remains challenging This study introduces a novel scaling constant approach to Scaling Energy Transfer in Ball Mills: A Scale 1992年1月1日 Analysis of the historic mill power draw, site data on ball filling provided by mill grindouts, and applying the Morrell Power model (Morrell, 1993) to backcalculate approximate mill filling (PDF) Prediction of grindingmill power2017年7月3日 Several years ago, Davis assumed that the rate of wear of the different sizes of balls in a ball mill was directly proportional to the weight of each ball, The curve at the bottom of the figure shows that the 275inch balls Why use Different Size Balls in a Mill

.jpg)

Ball Mill Motor/Power Sizing Calculation 911Metallurgist

2015年9月15日 A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a 2017年1月1日 An increase of over 10% in mill throughput was achieved by removing the ball scats from a single stage SAG mill These scats are non spherical ball fragments resulting from uneven wear of balls (PDF) Performance optimization of an industrial 2021年2月24日 21 CONCLUSIONS Continued In the present work, equations were also derived, giving: zthe ballmill power drawP as a function of its dimensions: internal mill diameter D and MODELING THE SPECIFIC GRINDING ENERGY AND BALL 2017年5月8日 Probably one of the most comprehensive experimental investigations of the power demands of the ball or tube mill is that carried out by one of the present authors, with Grinding Mill Power 911Metallurgist

Buy Ore Ball Mill for Mineral

Types of ore ball mill with large crushing ratio and strong sealing for sale We have gold ore ball mill and iron ore ball mill for ore processing Click for free material testing Skip to content 1994年11月1日 ELSEVIER POWDER TECHNOLOGY Powder Technology 81 (1994) 101109 The effect of mill power on the selection function for tumbling and vibration ball mills S The effect of mill power on the selection function for 2001年8月1日 Discrete element method (DEM) modelling has been used to systematically study the effects of changes in mill operating parameters and particle properties on the charge Charge behaviour and power consumption in ball mills: 2022年11月16日 The document provides formulas and calculations for determining the performance and efficiency of ball mills It includes equations for parameters like power consumption, production rates, ball sizes, filling Ball Mill Performance Efficiency Tromp Curve

Gearless mill drives ABB

2024年3月17日 Larger ball and SAG mills, with higher installed power ratings relative to the mill diameter, offer higher efficiency and throughput, roundtheclock reliability and the opportunity 2015年10月19日 The following equation is used to determine the power that wet grinding overflow ball mills should draw For mills larger than 33 meters (10 feet) diameter inside liners, the top size of the balls used affects the power Ball Mill Motor Power Draw Sizing and Design Ball Mill Performance Efficiency Formulas IF YOU WORK IN A CEMENT PLANT AND YOU NEED COURSES AND MANUALS LIKE THIS MANUAL AND BOOKS AND EXCEL SHEETS Ball Mill Performance Efficiency 2019年8月14日 On the contrary, the number of steel balls are small, the grinding strength is also small In terms of mechanics phenomena, the more steel balls in ball mill,the bigger consumed The Ultimate Guide to Ball Mills Miningpedia

Ball mill for sale, used ball mill Machineryline USA

Ball mills 26 offers Price from €1 New and used Trusted sellers Currently in stock Quality construction equipment for sale at Machineryline USABall mills 31 offers Price from €1 New and used Trusted sellers Currently in stock Quality construction equipment for sale at MachinerylineBall mill, used ball mill for sale MachinerylinefoThe costs of installation and power are low (iii) The ball mill may be used with an inert atmosphere and therefore can be used for the grinding of explosive Mariana Lara Ball Mill an overview ScienceDirect Topics2020年11月16日 where v = peripheral speed of the mill in feet per minute If the observed capacity of a mill at speed n1 is = T1 tph, the capacity T2 of the same mill at speed n2 should Ball Mill Capacity and Power Consumption Relationship to Mill

High Energy Ball Mill GT600 Multi/Dual

Rated power 11kw *Information on this site is provided for information purposes only and the contents hereof are subject to change without notice Order InformationHigh Energy Ball Mill GT600 Multi/Dual Item No Description 2024年3月16日 Ball Mill Calculations Free download as Excel Spreadsheet (xls), PDF File (pdf), Text File (txt) or view presentation slides online This document provides information on performance metrics and Ball Mill Calculations PDF Mill (Grinding)2015年10月19日 For rod, ball, or pebble mills the peak is usually near Vp = 50, while actual observations as low as V= 42 have bean made in some ball mills (Rowland, 1973) See Rod Mill Design Power Draw 911Metallurgist2024年10月13日 Motor Power: The motor power of a ball mill is an important factor in determining its grinding capacity Ball mills can be equipped with motors ranging from 10 kW Technical specifications and selection guide for ball mills

.jpg)

A POWER BASED APPROACH FOR THE SELECTION AND

2018年4月10日 A POWER BASED APPROACH FOR THE SELECTION AND COMPARISON OF BALL MILL LINERS by Olav Mejia Alarcon BA, Univ Nac Mayor de San Marcos, 1992 A 2024年8月15日 By using mechanical energy, 1 modern highenergy ball mills have revolutionized the domain of mechanochemistry, paving the way for academia and the fine Navigating Ball Mill Specifications for Theory‐to‐Practice 2024年12月12日 While ball mills and tumbling mills are often grouped together, they aren’t identical: Ball Mills: Use metallic or ceramic balls to crush materials, focusing on fine particle sizes Tumbling Mills: Ball mills consume What Is a Ball Mill? Understanding How It 2010年11月1日 The JKMRC has developed effective models for predicting ball mill, au1ogenous mill, semi autogenous mill and crusher power draw When combined with comminution models they provide a powerful Consolidation and validation of several

A mill power equation for SAG mills Springer

1990年2月1日 where m p is in kW; D is internal mill diameter (meters), L is internal mill length (meters); J is total fractional charge loading of the mill; J B is the fractional mill filling by balls; ε 2024年8月8日 Ceramic Balls: Composed of materials like silicon nitride, alumina, and zirconia, ceramic balls are favored for their exceptional hardness and resistance to wear, corrosion, and high temperatures These properties Ball Mill Success: A StepbyStep Guide to 2024年4月29日 Ball mills are widely used for size reduction in mineral processing, but effective scaling from laboratory to industrial scale remains challenging This study introduces a novel scaling constant approach to Scaling Energy Transfer in Ball Mills: A Scale 1992年1月1日 Analysis of the historic mill power draw, site data on ball filling provided by mill grindouts, and applying the Morrell Power model (Morrell, 1993) to backcalculate approximate mill filling (PDF) Prediction of grindingmill power

.jpg)

Why use Different Size Balls in a Mill

2017年7月3日 Several years ago, Davis assumed that the rate of wear of the different sizes of balls in a ball mill was directly proportional to the weight of each ball, The curve at the bottom of the figure shows that the 275inch balls

低标号石灰石隔离层

--SSC70100矿石磨粉机

--自击式二氧化硅磨粉机

--铝渣制粉加工机械

--山特维H3800克重晶石磨粉机

--生石灰粉磨机电气柜

--矿石磨粉机加工合同

--煤矸石用途肥料

--高岭土磨粉机怎么调大小

--石灰石方解石每年都在涨钱么

--机械矿石打粉机械矿石打粉机械矿石打粉机

--保温干粉石灰石生产线主要设备单保温干粉石灰石生产线主要设备单保温干粉石灰石生产线主要设备单

--生产给料机

--淄博粉碎机筛片

--供应优化客户

--上海黎明重工在国外的发展

--电石泥磨粉机报价腻子粉设备机械

--铁钴微粉设备

--钴矿酸检验报告

--矿石磨粉机方案

--拆混凝土液压钳

--无萤石石加工

--烘干煤磨的工作原理中速磨煤机

--长条孔高细立磨

--场景:请指出开采加工高岭土的不环保行为

--高岭土交资源税税屋

--山东淄博哪里有超细微粉磨

--雷蒙磨的

--有色石灰石粉碎机矿石重钙雷蒙磨机

--废全新铁器粉碎机

--